Motor Oil Quality Progresses With Engine Technology

ILSAC Standards for Passenger Car Motor Oil

|

| GF-6A |

May 1 2020 |

Backward compatible, provides protection for a variety of older and newer engines. The ILSAC GF-6A specification will replace the

ILSAC GF-5 specification and would provide a new performance level for engine oils for spark ignition internal combustion engines. GF-6A will have

improved performance against low-speed preignition (engine knock or pinging) in direct-injections (GDS) engines. GF-6A will have better fuel economy

performance as determined by the Sequence VIE test. Will cover all the previous GF-5 viscosity grades. GF-6A will have better resistance to viscosity

shear under high load at low RPM |

| GF-6B |

May 1 2020 |

Not backward compatible, for use in select new vehicles. The proposed ILSAC GF-6B will provide the same performance as GF-6A, but

with the added goal of having better high-temperature capability and better resistance to shear under stress, especially at low RPM, to deliver

better fuel economy. ILSAC GF-6B will only cover the 0W-16 viscosity grade oils. |

| GF-5 |

Introduced in October 2010 |

For 2011 and older vehicles, designed to provide improved high temperature deposit protection for pistons and turbochargers, more

stringent sludge control, improved fuel economy, enhanced emission control system compatibility, seal compatibility, and protection of engines

operating on ethanol-containing fuels up to E85 |

| GF-4 |

Obsolete |

Valid until September 30, 2011. Use GF-5 where GF-4 is recommended |

| GF-3 |

Obsolete |

Use GF-5 where GF-3 is recommended |

| GF-2 |

Obsolete |

Use GF-5 where GF-2 is recommended |

| GF-1 |

Obsolete |

Use GF-5 where GF-1 is recommended |

API Engine Oil Service Category Chart

|

| "S" |

Status |

Service Gasoline Engines |

| SP |

May 1, 2020 |

Category SP oil specifications were created to closely match the ILSAC GF-6 specifications required by the latest engines produced by U.S. and

Japanese auto makers. For more information see ILSAC GF-6A & GF-6B above. |

| SN |

Introduced October 2010 |

Category SM were ntroduced in October 2010 for 2011 and older vehicles, designed to provide improved high temperature deposit protection for

pistons, more stringent sludge control, and seal compatibility. API SN with Resource Conserving matches ILSAC GF-5 by combining API SN performance

with improved fuel economy, turbocharger protection, emission control system compatibility, and protection of engines operating on ethanol-containing

fuels up to E85 |

| SM |

Introduced on 30 November 2004 |

Category SM oils are designed to provide improved oxidation resistance, improved deposit protection, better wear protection, and better

low-temperature performance over the life of the oil. Some SM oils may also meet the latest ILSAC specification and/or qualify as Energy Conserving.

They may be used where API Service Category SJ and SL earlier categories are recommended. |

| SL |

2001 Gasoline Engine Service |

Category SL was adopted to describe engine oils for use in 2001. It is for use in service typical of gasoline engines in present and earlier

passenger cars, sports utility vehicles, vans and light trucks operating under vehicle manufacturers recommended maintenance procedures. Oils meeting

API SL requirements have been tested according to the American Chemistry Council (ACC) Product Approval Code of Practice and may utilize the API Base

Oil Interchange and Viscosity Grade Engine Testing Guidelines. They may be used where API Service Category SJ and earlier categories are

recommended.. |

| SJ |

1997 Gasoline Engine Service |

Category SJ was adopted in 1996 to describe engine oil first mandated in 1997. It is for use in service typical of gasoline engines in present

and earlier passenger cars, vans, and light trucks operating under manufacturers recommended maintenance procedures. Oils meeting API SH requirements

have been tested according to the American Chemistry Council (ACC) Product Approval Code of Practice and may utilize the API Base Oil Interchange and

Viscosity Grade Engine Testing Guidelines. They may be used where API Service Category SH and earlier categories are recommended. |

| SH |

Obsolete |

For model year 1996 and older engines. |

| SG |

Obsolete |

For model year 1993 and older engines. |

| SF |

Obsolete |

For model year 1988 and older engines. |

| SE |

Obsolete |

For model year 1979 and older engines. |

| SD |

Obsolete |

For model year 1971 and older engines. |

| SC |

Obsolete |

For model year 1967 and older engines. |

| SB |

Obsolete |

For older engines. Use only when specifically recommended by the manufacturer. |

| SA |

Obsolete |

For older engines; no performance requirement. Use only when specifically recommended by the manufacturer. |

| "C" |

Status |

Service Diesel Engines |

| FA-4 |

Current - 2016 |

API FA-4 describes certain XW-30 oils specifically formulated for use in select high-speed four-stroke cycle diesel engines designed to meet 2017

model year on-highway greenhouse gas (GHG) emission standards. These oils are formulated for use in on-highway applications with diesel fuel sulfur

content up to 15 ppm. Refer to individual engine manufacturer recommendations regarding compatibility with API FA-4 oils.

- API FA-4 oils are blended to a high temperature high shear (HTHS) viscosity range of 2.9cP-3.2cP to assist in reducing GHG emissions. These oils

are especially effective at sustaining emission control system durability where particulate filters and other advanced aftertreatment systems are

used. API FA-4 oils are designed to provide enhanced protection against oil oxidation, viscosity loss due to shear, and oil aeration as well as

protection against catalyst poisoning, particulate filter blocking, engine wear, piston deposits, degradation of low- and high-temperature

properties, and soot' related viscosity increase.

- API FA-4 oils are neither interchangeable nor backward compatible with API CK-4, CJ-4, CI-4 with CI-4 PLUS, CI-4, and CH-4 oils. Refer to engine

manufacturer recommendations to determine if API FA-4 oils are suitable for use. API FA-4 oils are not recommended for use with fuels having greater

than 15 ppm sulfur. For fuels with sulfur contents greater than 15 ppm, refer to engine manufacturer recommendations.

|

| Ck-4 |

Current - 2016 |

API CK-4 describes oils for use in high-speed four-stroke cycle diesel engines designed to meet 2017 model year on-highway and Tier 4 non-road

exhaust emission standards as well as for previous model year diesel engines. These oils are formulated for use in all applications with diesel fuels

ranging in sulfur content up to 500 ppm. However, the use of these oils with greater than 15 ppm sulfur fuel may impact exhaust aftertreatment system

durability and/or oil drain interval.

- API CK-4 oils are especially effective at sustaining emission control system durability where particulate filters and other advanced

aftertreatment systems are used. API CK-4 oils are designed to provide enhanced protection against oil oxidation, viscosity loss due to shear, and

oil aeration as well as protection against catalyst poisoning, particulate filter blocking, engine wear, piston deposits, degradation of low- and

high-temperature properties, and soot-related viscosity increase.

- API CK-4 oils exceed the performance criteria of API CJ-4, CI-4 with CI-4 PLUS, CI-4, and CH-4 and can effectively lubricate engines calling for

those API Service Categories. When using CK-4 oil with higher than 15 ppm sulfur fuel, consult the engine manufacturer for service interval

recommendations.

|

| CJ-4 |

Current - 2006 |

Introduced in 2006 for high-speed four-stroke engines. Designed to meet 2007 on-highway exhaust emission standards. CJ-4 oils are compounded for

use in all applications with diesel fuels ranging in sulphur content up to 500ppm (0.05% by weight). However, use of these oils with greater than

15ppm sulfur fuel may impact exhaust after treatment system durability and/or oil drain intervals. CJ-4 oils are effective at sustaining emission

control system durability where particulate filters and other advanced after treatment systems are used. CJ-4 oils exceed the performance criteria of

CF-4, C-4, AH-4 and C-4. |

| C-4 Plus |

Current - 2004 |

Used in conjunction with API C-4, the " C-4 PLUS" designation identifies oils formulated to provide a higher level of protection against

soot-related viscosity increase and viscosity loss due to shear in diesel engines. Like Energy Conserving, C-4 PLUS appears in the lower portion of

the API Service Symbol "Donut." |

| C-4 |

Severe-Duty Diesel Engine Service |

The C-4 performance requirements describe oils for use in those high speed, four-stroke cycle diesel engines designed to meet 2004 exhaust

emission standards, to be implemented October 2002. These oils are compounded for use in all applications with diesel fuels ranging in sulfur content

up to 0.05% by weight. These oils are especially effective at sustaining engine durability where Exhaust Gas Recirculation (EGR) and other exhaust

emission componentry may be used. Optimum protection is provided for control of corrosive wear tendencies, low and high temperature stability, soot

handling properties, piston deposit control, valve train wear, oxidative thickening, foaming and viscosity loss due to shear. C-4 oils are superior

in performance to those meeting API AH-4, C-4 and CF-4 and can effectively lubricate engines calling for those API Service Categories. |

| AH-4 |

Severe-Duty Diesel Engine Service |

This service oils are suitable for high speed, four-stroke diesel engines designed to meet 1998 exhaust emission standards and are specifically

compounded for use with diesel fuels ranging in sulfur content up to 0.5% weight. AH-4 oils are superior in performance to those meeting API CF-4 and

API C-4 and can effectively lubricate engines calling for those API Service Categories. |

| C-4 |

1994 Severe-Duty Diesel Engine Service |

This category describes oils for use in high speed four-stroke-cycle diesel engines used in both heavy-duty on-highway (0.05% wt sulfur fuel) and

off-highway (less than 0.5% wt sulfur fuel) applications. C-4 oils provide effective control over high temperature piston deposits, wear, corrosion,

foaming, oxidation stability, and soot accumulation. These oils are specially effective in engines designed to meet 1994 exhaust emission standards

and may also be used in engines requiring API Service Categories CD, CE, and CF-4. Oils designed for this service have been in existence since

1994. |

| CF-2 |

Obsolete |

Service typical of two-stroke cycle diesel engines requiring highly effective control over cylinder and ring-face scuffing and deposits. Oils

designed for this service have been in existence since 1994 and may be used when API Service Category CD-II is recommended. These oils do not

necessarily meet the requirements of API CF or CF-4 unless they pass the test requirements for these categories. |

| CF |

Indirect-Injected Diesel Engine Service |

Service typical of indirect-injection diesel engines and other diesel engines that use a broad range of fuel types, including those using fuel

with high sulfur content; for example, over 0.5% wt. Effective control of piston deposits, wear and copper-containing bearing corrosion is essential

for these engines, which may be naturally aspirated, turbocharged or supercharged. Oils designated for this service have been in existence since 1994

and may be used when API Service Category CD is recommended. |

| CF-4 |

1990 Diesel Engine Service |

Service typical of high speed, four-stroke cycle diesel engines. API CF-4 oils exceed the requirements for the API CE category, providing

improved control of oil consumption and piston deposits. These oils should be used in place of API CE oils. They are particularly suited for

on-highway, heavy-duty truck applications. When combined with the appropriate S category, they can also be used in gasoline and diesel powered

personal vehicles i.e., passenger cars, light trucks and vans when recommended by the vehicle or engine manufacturer. |

| CE |

Obsolete |

Service typical of certain turbocharged or supercharged heavy-duty diesel engines, manufactured since 1983 and operated under both low speed,

high load and high speed, high load conditions. Oils designed for this service may also be used when API Service Category CD is recommended. |

| CD-II |

Obsolete |

Service typical of two-stroke cycle diesel engines requiring highly effective control of wear and deposits. Oils designed for this service also

meet all performance requirements of API Service Category CD. |

| CD |

Obsolete |

Service typical of certain naturally aspirated, turbocharged or supercharged diesel engines where highly effective control of wear and deposits

is vital, or when using fuels with a wide quality range (including high-sulfur fuels). Oils designed for this service were introduced in 1955 and

provide protection from high temperature deposits and bearing corrosion in these diesel engines. |

| CC |

Obsolete |

Service typical of certain naturally aspirated, turbocharged or supercharged diesel engines operated in moderate to severe-duty service, and

certain heavy-duty gasoline engines. Oils designed for this service provide protection from bearing corrosion, rust, corrosion and from high to low

temperature deposits in gasoline engines. They were introduced in 1961. |

| CB |

Obsolete |

Service typical of diesel engines operated in mild to moderate duty, but with lower quality fuels, which necessitate more protection from wear

and deposits; occasionally has included gasoline engines in mild service. Oils designed for this service were introduced in 1949. They provide

necessary protection from bearing corrosion and from high temperature deposits in naturally aspirated diesel engines with higher sulfur fuels. |

| CA |

Obsolete |

Service typical of diesel engines operated in mild to moderate duty with high quality fuels; occasionally has included gasoline engines in mild

service. Oils designed for this service provide protection from bearing corrosion and ring-belt deposits in some naturally aspirated diesel engines

when using fuels of such quality that they impose no unusual requirements for wear and deposits protection. They were widely used in the 1940s and

1950s but should not be used in any engine unless specifically recommended by the equipment manufacturer. |

|

The history of lubrication can be traced back as far as the very beginning of transportation. Archaeologists at the site of the Egyptian tomb of

Tehuti-Hetep (ca. 1650 B.C.) learned that the ancient Egyptians used olive oil as a lubricant to aid in the movement of large stones, statues and

building materials. These Egyptians also made use of beef and mutton tallow as axle grease in their chariots. A movement ahead in time to the

writings of Herdotus (484-424 B.C.) indicates that people living 500 years before the birth of Christ had discovered the lubrication effectiveness of

oils produced from petroleum.

Until the nineteenth century, lubricants were still primarily made of animal fats such as sperm oil and lard oil and vegetable oils such as

rapeseed and castor oil. The search for better and less expensive lubricants prompted the Pennsylvania Rock Oil Company to pursue searching for

natural petroleum oil in the ground. When Edwin L. Drake's crew successfully drilled for oil in 1859, a new industry and a new means of lubrication

were born.

Petroleum-based lubricants continued to be used successfully in the earliest automobiles, and even then, extensive efforts were made to classify

them. Viscosity was identified as one of the most important characteristics of a motor oil, and oils were divided into light, medium and heavy

viscosity classes. As soon as instruments capable of measuring viscosity were introduced, the Society of Automotive Engineers (SAE) developed a

complete viscosity classification system, which included 11 different viscosity grades: SAE 0W, SAE 5W, SAE 10W, SAE 15W, SAE 20W, SAE 25W, SAE 20,

SAE 30, SAE 40, SAE 50, and SAE 60.

Oil viscosity grades with a "W" were formulated for cold temperatures, while viscosity grades without the "W" were suited for higher temperatures.

Before the development of viscosity modifiers in the 1940s allowed the manufacture of multi-grade motor oils, motorists commonly had to switch

viscosity grades in their vehicles with the seasons. U.S. oil companies have been marketing multi-viscosity oils, such as SAE 5W-30, SAE 10W-40 and

SAE 20W-50, since 1945. These oils offer adequate protection in both high and low temperatures.

As the years went by, engine technology improved. In order to meet public demand for vehicles with greater fuel economy during the oil embargo of

the 1970s, automobile manufacturers produced smaller, lighter cars powered by smaller and more efficient engines. When fuel injection became common

on gasoline-fueled engines, it offered motorists quick starts and quick mobility. These changes placed even greater demand on the vehicle's engine

oil as it was required to flow and reach critical components as quickly as possible.

Today, demand for high performance, fuel efficient and more environmentally-friendly vehicles is as high as ever. To meet this demand, vehicle

manufacturers have produced more aerodynamic cars with reduced air flow through the engine. Although these vehicles are more fuel efficient, they

exhibit higher engine operating temperatures than earlier automobiles, putting even greater stresses on the engine oil in the areas of oxidation

stability, deposit prevention and wear protection.

As automotive technology continues changing, engine oil technology has had to change as well. Over the years, manufacturers of higher quality oils

have begun switching from Group I base stocks to Group II and Group III base stocks. Like Group I base stocks, Group II and III base stocks are

mineral-based, but they contain less saturates, sulfur and paraffins and have higher viscosity indices, meaning they perform better than Group I base

stocks, particularly in the areas of thermal and oxidative stability and cold temperature service. The introduction of synthetic motor oils to the

marketplace has brought superior quality Group IV and V base stocks to the blending process.

In order to address the changing service and lubrication requirements of modern automobiles, and to allow effective communication among engine

manufacturers, the oil industry and consumers, the API Engine Service Classification System (ESCS) was established in 1970. The system was designed

to classify oils according to their performance characteristics and type of service for which they were blended. Later, in 1993, the AIl Engine Oil

Licensing and Certification System (EOLCS) was launched, a voluntary program which allows marketers who meet the minimum performance requirements to

mark their oil containers with the API certification marks.

API service categories for gasoline engines are comprised of two letters. The first letter is "S" for "service" and the second letter is assigned

alphabetically according to order of development. Thus, the first service category of "SA" is the earliest, while the latest is "SL." Later service

categories exceed the performance requirements of previous categories and can be used in place of the earlier ones.

Where Do Synthetics Fit In?

Synthetic motor oils offer the best overall protection for today's high revving, hard working engines, but how do synthetic lubricants fit into

the big picture?

In 1877, the prominent chemist team of Charles Friedel and James Mason Crafts successfully used aluminum trichloride as a catalyst, creating the

first known synthesized hydrocarbons. It wasn't until 1929 that Standard Oil Company of Indiana commercialized the process, but the endeavor was

unsuccessful due to lack of demand.

The Zurich Aviation Congress became interested in the development of ester-based lubricants in 1937. The Germans, frustrated by the failure of

petroleum lubricants during the cold weather of the Battle of Stalingrad, prepared and evaluated more than 3500 esters between 1938 and 1944.

Meanwhile, in the United States, the first diester base stocks (a compound using two ester groupings) were in development at the Naval Research

Laboratory.

By 1947, Great Britain had discovered the benefits of using diesters as lubricants in turboprop aircraft. Later, with the advent of highly

sophisticated jet engines, research and development in the area of synthetic lubricants really took off, and various synthetic formulations were

developed to meet the demands of the new engines.

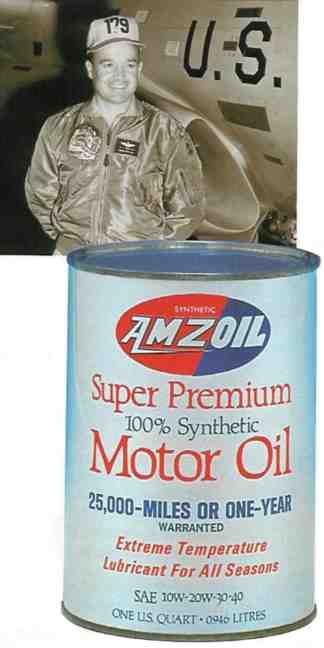

The clear benefits of synthetic-based lubricants in jet engines impressed lieutenant colonel and jet fighter squadron commander Al Amatuzio, and

by the mid-1960s, he became interested in developing a synthetic motor oil for use in internal combustion engines. Given the significant differences

between a jet engine and an internal combustion engine, it was a massive task, but Amatuzio was up to the challenge. By 1972, after several years of

intense research and development, AMSOIL Synthetic Motor Oil was born, and it became the first 100 percent synthetic-based motor oil to pass American

Petroleum Institute (API) service requirements.

When it first hit the market, AMSOIL was far ahead of its time, and Amatuzio found it difficult to market such a revolutionary product. But with

the complexity of engines increasing, forcing smaller engine designs and ever-increasing engine operating temperatures, engines demanded a superior

lubricant, and people slowly discovered it in AMSOIL. AMSOIL had found its niche and began to grow, later branching out into the synthetic diesel

oil, two-cycle oil and transmission fluid markets. Competitors were forced to take notice, and soon industry giants Mobil, Quaker State, Castrol,

Valvoline and Pennzoil were marketing their own synthetic variations.

Today, synthetic lubricants continue to become more and more mainstream. In fact, to ensure its vehicles receive the best protection, Corvette

requires the use of synthetic motor oil in its engines. Other high performance vehicle manufacturers have followed suit, and even General Motors,

Ford and Chrysler require synthetic lubricants for certain vehicle components. The vehicles of the future will continue to have smaller engines,

lower emission requirements, higher performance characteristics and better fuel economy, and they will require lubrication quality only a synthetic

can offer.

AMSOIL continues to lead the way in the synthetic market. Not content merely being "The First in Synthetics®," AMSOIL is dedicated to being

the very best in synthetics as well. AMSOIL Motor Oils outperform competing conventional and synthetic oils, offering motorists the ultimate in wear

protection, all-temperature performance, maximum fuel efficiency and extended drain intervals.

Informative Tech Articles | | Car Shows | My Car Projects | |

|

|

|